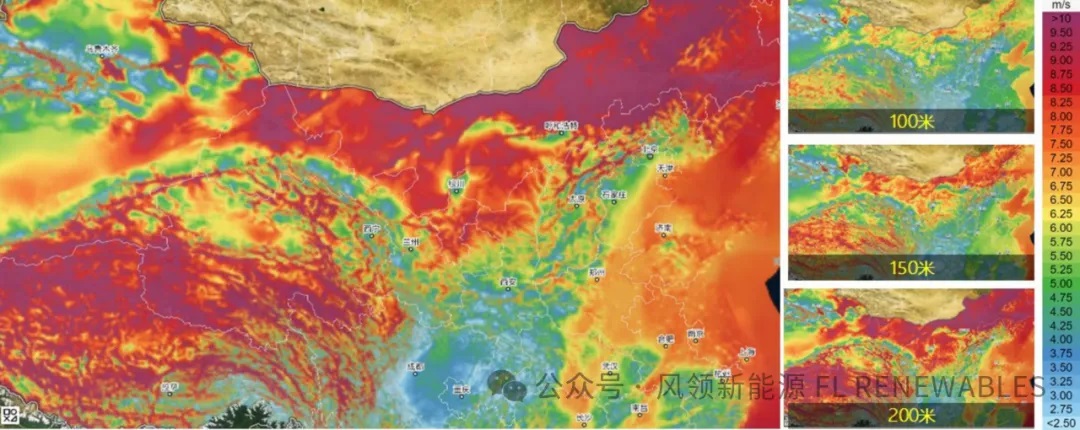

"As the development of wind power in China gradually tilts towards low wind speed areas, regions represented by Henan, Anhui, Shandong, Jiangsu and other central and eastern low wind speed and high shear areas will be the focus of future wind power industry development. About 68% of the low wind speed resources in China are located in areas suitable for development, and within the next 5 to 10 years, concrete towers taller than 140 meters will become the mainstream choice for developing China's low wind speed wind fields due to their height advantage, good economic performance, and stable support."

Wind speed distribution map: Every increase of 100 meters in height, the utilization rate of wind resources increases tenfold

Development History of Concrete Towers

Wind power hybrid tower were born in Europe last century. In 1990, Germany's Enercon produced a hybrid tower with a hub height of 65m and a power capacity of 650kW. After entering China, after more than a decade of R&D exploration, significant breakthroughs have been made in reducing LCOE (cost of electricity) and increasing power generation efficiency. Shanghai FL RENEWABLES, besides learning and adopting foreign cutting-edge technology, continuously conducts independent R&D and innovation. Currently, the height of the hybrid towers we have delivered has reached 180 meters, with a maximum capacity of 7.25MW, and the concrete strength has reached the French standard UHPC150.

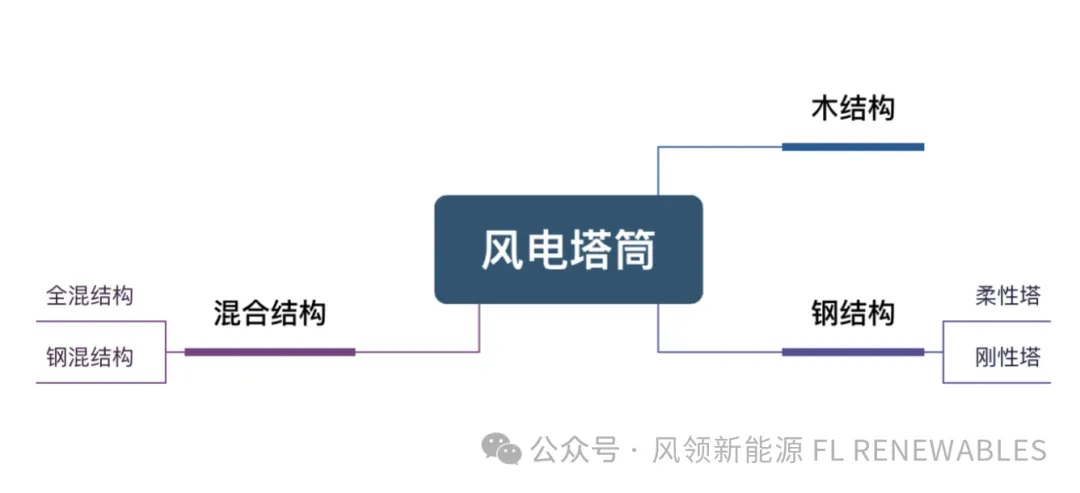

(Wind tower structural classification)

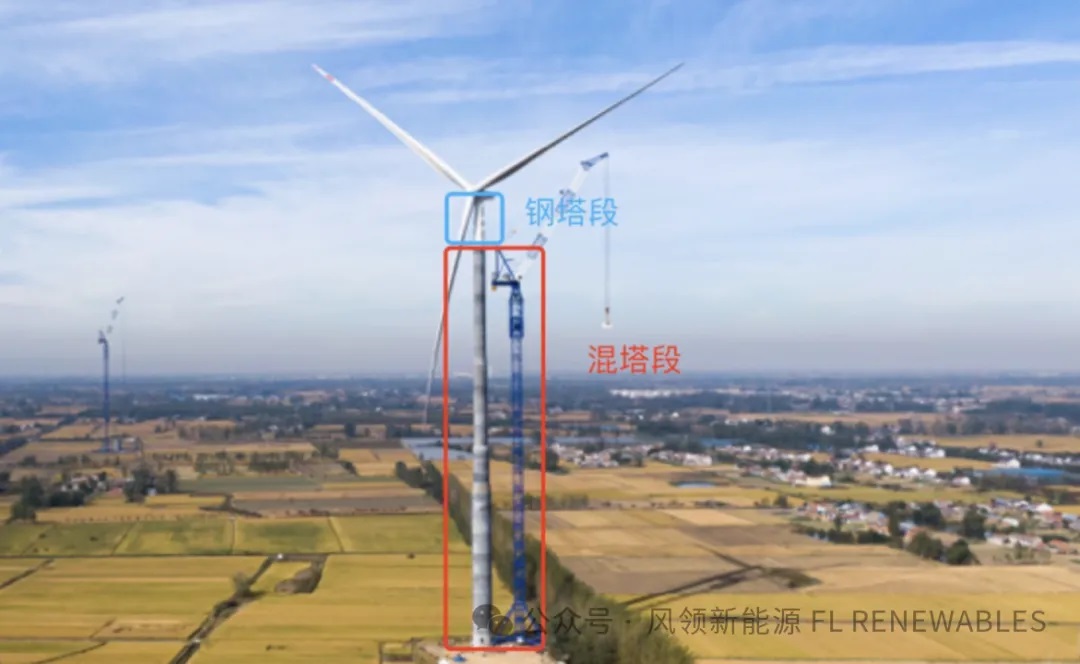

Structure of the Concrete Tower Wind Turbine

A wind turbine is composed of three parts: the tower, the main body, and the blades. The tower is the supporting structure of the turbine and provides important safeguard for its safety. With the development of larger wind turbines, longer blades, and taller towers, hybrid towers have become the more economical and safer choice. The upper part of the hybrid tower is composed of steel sections and wheel hub, while the lower part is made of concrete sections.

(The world's first UHPC150 material hybrid tower wind turbine by Shanghai FL RENEWABLES)

Take the 180-meter hybrid tower wind turbine produced by Shanghai FL RENEWABLES in the Lianshui project in Jiangsu as an example, the center height of the wheel hub is 180 meters, the hybrid tower section is 157.4 meters; it uses 78 tons of steel and 806 cubic meters of concrete. The hybrid tower section is completed by splicing C-type/O-type precast pipe sections.

(Transportation process of FL RENEWABLES precast segments)

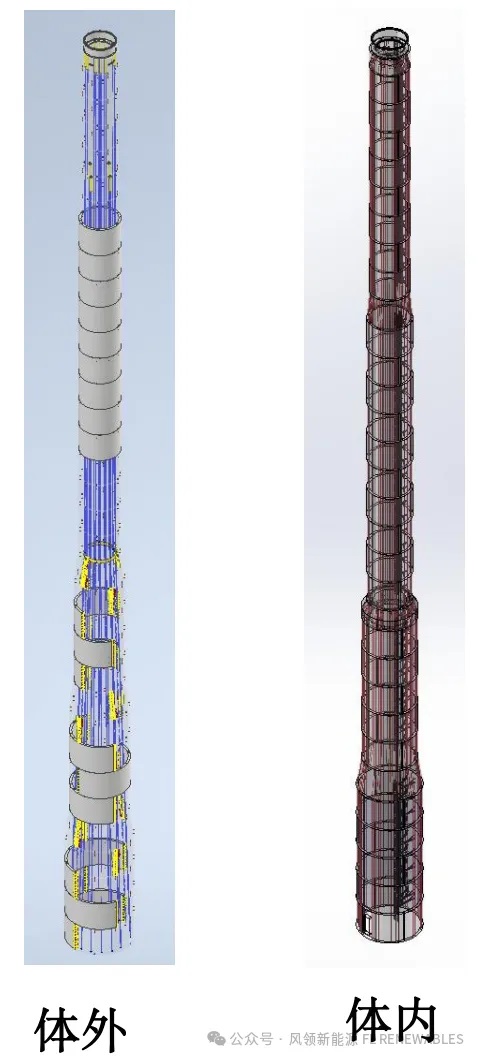

Safety Assurance of Hybrid Towers: Internal Pre-stress System + UHPC

Due to the characteristics of concrete materials: high stiffness and weak tensile strength. To enhance the safety of the tower, pre-stressing is applied after the assembly of the pipe sections. FL RENEWABLES uses an adherent internal pre-stress system, where the interior pre-stress will fix steel cables in the pre-reserved holes inside the tower, and after fixing the cables, cement grouting is used to fill the gaps. The grouting material integrates the steel strands with the tower; and the adhering pre-stress ensures the controllability of pre-stress loss, significantly enhancing the tower's durability.

(Internal pre-stress system: the steel strands are inside, isolated from the external corrosive environment)

Material-wise, FL RENEWABLES uses UHPC material which adds metal materials such as steel fibers to traditional concrete, greatly increasing the density and tensile strength of the concrete, preventing shedding and cracking. Additionally, UHPC material also has excellent corrosion resistance, impermeability, and freeze-thaw resistance, maintaining its safety even under extreme natural conditions.

(Shanghai FL RENEWABLES UHPC ultra-high performance concrete with steel fiber)

More stable operating state and lower maintenance costs

Good mechanical properties of concrete wind towers, with a low risk of fatigue failure during the design life; better vibration and corrosion resistance of concrete materials than steel, no fasteners on the body, eliminating the need for maintenance and inspection, extending the main unit's lifespan and significantly reducing operational maintenance costs.

Higher Power Generation

The great stiffness of concrete towers allows for an optimized design that can keep the structural first-order frequency within an acceptable range, reducing power loss caused by no frequency crossover. Additionally, the good stability of hybrid towers can significantly reduce top swing amplitude, extending the fatigue life of the unit and increasing power generation.

Greater Carrying Capacity and Safety

Concrete material can better meet the stability needs of large wind turbines; it can bear the installation weight of larger blades. The connection with the foundation is convenient and reliable, with good overall integrity and no sudden changes in stiffness, reducing the risk of foundation overturning accidents.

Lower Transportation Costs and Shorter Project Cycles

Precast sections can be adapted to local conditions, allowing for either assembly at the machine site or nearby in the yard; there are no special requirements for transportation routes, with each section of concrete tower not exceeding 4 meters in height, allowing the main machine to pass through. Also, the raw materials required for the concrete towers can be sourced locally, reducing project transportation costs and construction periods.

The company has been awarded as a "Specialized, Fine, Peculiar and Innovative" enterprise by Shanghai City, having received the "AAA Quality Service Integrity Unit", the "AAA Grade Emphasis on Quality and Credit Unit", and the "AAA Grade Contract and Trustworthy Enterprise" honors. The company possesses 134 authorized patents: among them, 84 utility model patents, 38 appearance design patents, and 12 invention patents. It is the leading unit in drafting national standards such as "Technical Specification for Prestressed Cast-in-Place Concrete Towers for Wind Turbines" and "Technical Specification for Prestressed Assembled Concrete Towers for Wind Turbines". The products are technologically advanced and of high quality, all have been certified by Germany's TüV Rheinland, filling multiple gaps in the domestic and overseas wind power equipment industry.

In the future, FL RENEWABLES will continue to iterate its technology, providing efficient, high-quality, and cost-effective new energy solutions domestically and abroad, bringing higher, safer, and more stable power generation revenues to owners.